Working principle of pipeline permanent magnet automatic iron remover

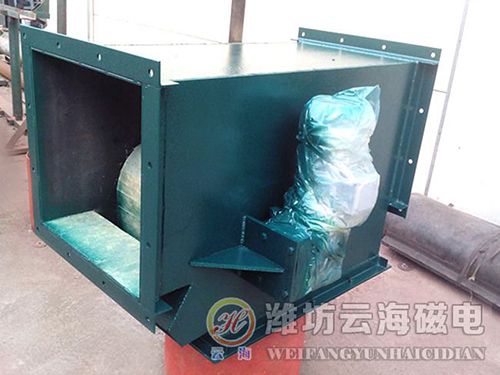

Pipeline permanent magnet automatic iron remover is a high-performance automatic magnetic separation device, which can be widely used in cement, electric power, ceramics, brick, chemical, food, glass, metallurgy, steel and other industries. It is the material purification and guarantees the safety of subsequent equipment. The preferred iron removal equipment to operate.

When the material flows through the iron remover, the ferromagnetic substance therein is adsorbed to the stainless steel pipe wall of the pipe separator, and gradually slides toward the tap hole as the permanent magnet moves to realize separation from the material. At the tapping point, due to the permanent magnet moving away from the direction of the circular motion, the ferromagnetic material loses its magnetic attraction and is discharged from the taphole under the action of gravity to realize automatic iron removal of the material.

The main features are:

(1) The device uses high remanenced NdFeB as a magnetic source, which has high iron removal efficiency and long service life.

(2) The power source adopts low-power cycloidal pin gear reducer motor. The transmission adopts precision roller chain, which has the advantages of small size, light weight, reliable and stable operation, small failure, etc. The user is easy to use and easy to maintain.

(3) The structure of the equipment is reasonable, compact and easy to install. It can be used in series with the material conveying pipeline.

(4) The iron removal process of the iron remover is continuous and automatic, and there is no need to look after the equipment after starting.

(5) Applicable to closed material conveying system, no dust escapes during work, no environmental pollution.