CTB wet magnetic separator

product description

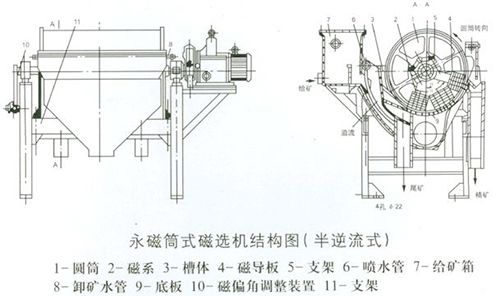

CTB series permanent magnetic cylinder magnetic separator magnetic field is divided into two types: rotary type and fixed type. The fixed type is mainly suitable for weak magnetic field wet sorting of fine magnetic particles or removal of strong magnetic minerals in non-magnetic minerals. When flowing into the magnetic field region, the ferromagnetic mineral is adsorbed on the surface of the cylinder, and the weak magnetic and non-magnetic minerals are sorted and excluded, and the ferromagnetic mineral adsorbed on the surface of the cylinder is taken out of the magnetic field region as the cylinder rotates. Rotary type is suitable for dry selection of fine-grained (medium-strong) magnetic minerals. Due to the high-speed rotation, the magnetic rolling times of magnetic particles are much higher than that of ordinary magnetic separators. This is significant for the magnetic agglomeration of the broken ring and the improvement of the rich ratio. The effect is that after being sorted, the mineral is separated into two kinds of magnetic materials and non-magnetic materials, which are respectively discharged from the respective discharge ports, and are suitable for rough selection and selection of ore granularity of 0.6-6 mm. The same cylinder can be equipped with three tanks, that is, the downstream flow tank (CTS) has a particle size of ≤6 mm, the countercurrent flow (CTN) has a particle size of ≤0.6 mm, and the semi-counterflow tank (CTB) has a particle size of ≤1 mm.

The principle is that when the slurry enters the magnetic zone, the ferromagnetic mineral is adsorbed on the surface of the cylinder, the weak magnetic and non-magnetic minerals are thrown off, and the ferromagnetic mineral adsorbed on the surface of the cylinder is rotated with the cylinder and taken out. The magnetic field area is flushed into the concentrate tank with flushing water to complete the sorting operation.

The same cylinder can be equipped with three tanks, namely a co-current tank (CTS), a counter-flow tank (CTN) and a semi-counterflow tank (CTB) to suit different sorting requirements.

The downstream tank is suitable for rough selection and selection of ore size of 6~0mm.

The counterflow tank is suitable for rough selection and sweeping of ore particle size of 0.6~0mm, and heavy medium recovery of coal preparation industry.

The semi-plastic flow cell is suitable for rough selection and selection of ore particle size of 0.5~0mm, especially for the selection of minerals with particle size of 0.15~0mm.

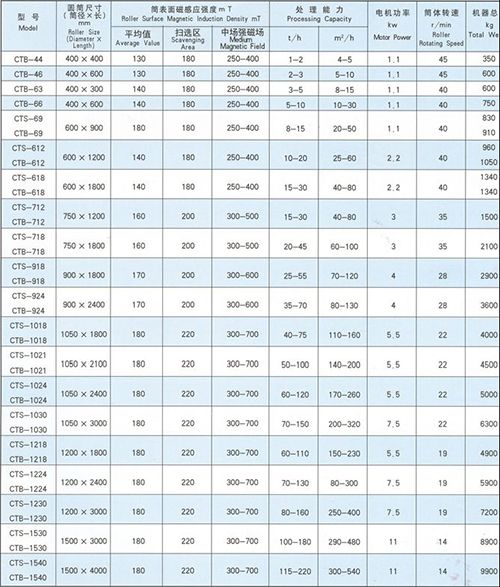

The main technical parameters: